"Interpreting X-ray images correctly"

We get to the bottom of things! Using high-resolution micro-/nanofocus X-ray technology and 3D computed tomography (CT), we investigate components from a wide range of industries down to the smallest detail. Our customers come from the electronics, automotive or aerospace industries and have relied on our high-tech test method for 20 years. Our claim: To constantly set new standards for your quality assurance.

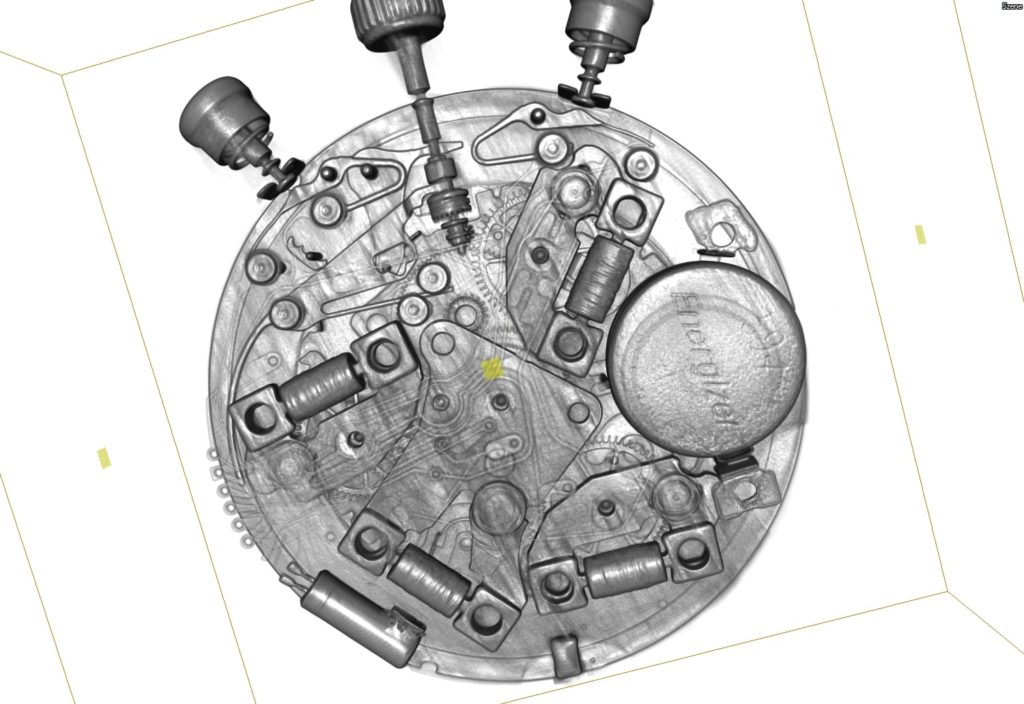

In our X-ray laboratory in Premstätten near Graz, we conduct industrial X-ray-/ and CT analysis. We scan different materials non-destructively and within a very short time. Possible defects become visible immediately. In contrast to optical inspection, no structure remains hidden with our test method.

Get certainty with just one scan – Our experienced experts provide you with the results immediately as digital X-ray images. This gives you reliable inspections and saves valuable time in quality assurance.

You are probably familiar with the classic CT examination at the doctor’s office, where an X-ray tube moves around the patient and takes images using X-rays. Per rotation, several thousand sectional images can be recorded in a small space. This works in a similar way in industrial computed tomography. With our modern CT scanning system, we are able to capture the complete geometry of a component geometry in the shortest possible time without destroying it.

Copyright © 2024 X-ray Service GmbH

Made by marketur.at